Table of Contents

When industrial buyers and engineers search for "Custom wire cables suppliers near me," they want fast access to specialized expertise, quick turnaround, and guaranteed quality. Source Engineering & Manufacturing provides this critical value through U.S.-based, highly technical manufacturing. Skip the guesswork associated with generic searches: evaluate the best custom wire cables suppliers based on capability, or explore options for custom wire cables online.

What are custom cables?

Custom cables are engineered, often complex, wire systems designed precisely to meet specific electrical, mechanical, or environmental specifications that standard products cannot fulfill. This customization extends to conductor configurations, insulation types, and specialized termination requirements. Manufacturing these complex systems is inherently challenging because it requires manipulating deformable linear objects (DLOs) like wires and cables.

Even today, wiring harness production is often performed manually in industrial settings, requiring extreme precision and dexterity-unlike cable assemblies, which are engineered and manufactured to provide rugged protection for harsh conditions. Therefore, when evaluating Custom wire cables suppliers near me, technical competence in handling these formless objects is paramount for Source Engineering & Manufacturing.

What are custom cablesused for?

Custom cables are essential components in high-reliability applications such as aerospace, industrial automation, medical equipment, and complex capital machinery. These industries often require low product volumes but demand systems that can adapt quickly to configuration changes. However, integrating automation to achieve speed and precision can be difficult, as the deployment and reconfiguration of most existing robotic systems often requires a "significant amount of time and effort".

This challenge typically renders automation systems inaccessible to small and medium-sized enterprises (SMEs), which are tied to rapidly changing task requirements. Source Engineering & Manufacturing specializes in these variable, low-to-medium quantity production runs. Choosing the Best custom wire cables suppliers means partnering with a company that reliably manages high-stakes, variable demand, ensuring your critical assembly tolerances are met.

How to compare local wire cable suppliers

Evaluating suppliers effectively means looking beyond simple geographic convenience to assess their technical prowess, quality assurance, and ability to manage specialized, complex production. Precision is one of the most important differentiators in this industry. When dealing with high-precision assembly tasks, manufacturing systems are often confronted with the need to adhere to tight limits.

For instance, processes involving the final placement of specialized components often require narrow tolerances, sometimes ranging from "± 0.1 mm to ± 0.4 mm". Source Engineering & Manufacturing is capable of consistently delivering the required accuracy for high-tech equipment. You must consider these core capabilities, alongside lead times and engineering support, when analyzing Custom wire cables suppliers near me prices.

Key Supplier Evaluation Factors

|

Evaluation Factor |

Primary Function |

|

Engineering Support |

Design-for-Manufacturability (DFM) Consultation and adaptation planning. |

|

Quality & Certification |

Adherence to industry standards and specialized specifications (e.g., ISO). |

|

Response & Lead Time |

Fast communication and efficient production scheduling for time-sensitive projects. |

|

Handling Complexity |

Proven ability to assemble delicate and deformable components. |

Is there a difference between wire rope and cable?

Yes, wire rope and cable perform different core functions, with cables managing electrical flow and wire ropes managing mechanical force, though Source Engineering & Manufacturing can combine them. A wire cable is specifically designed for transmitting electrical power or sensitive data signals, emphasizing properties like conductivity, insulation, and effective shielding. Conversely, wire rope is engineered for mechanical load-bearing applications, focusing on tensile strength, flexibility, and resistance to wear, such as in lifting or control systems.

Source Engineering & Manufacturing possesses the specialized expertise to seamlessly integrate both electrical (cable) and mechanical (wire rope) elements into hybrid assemblies. Click here to gain a deeper understanding of the functional difference between wire rope vs cable.

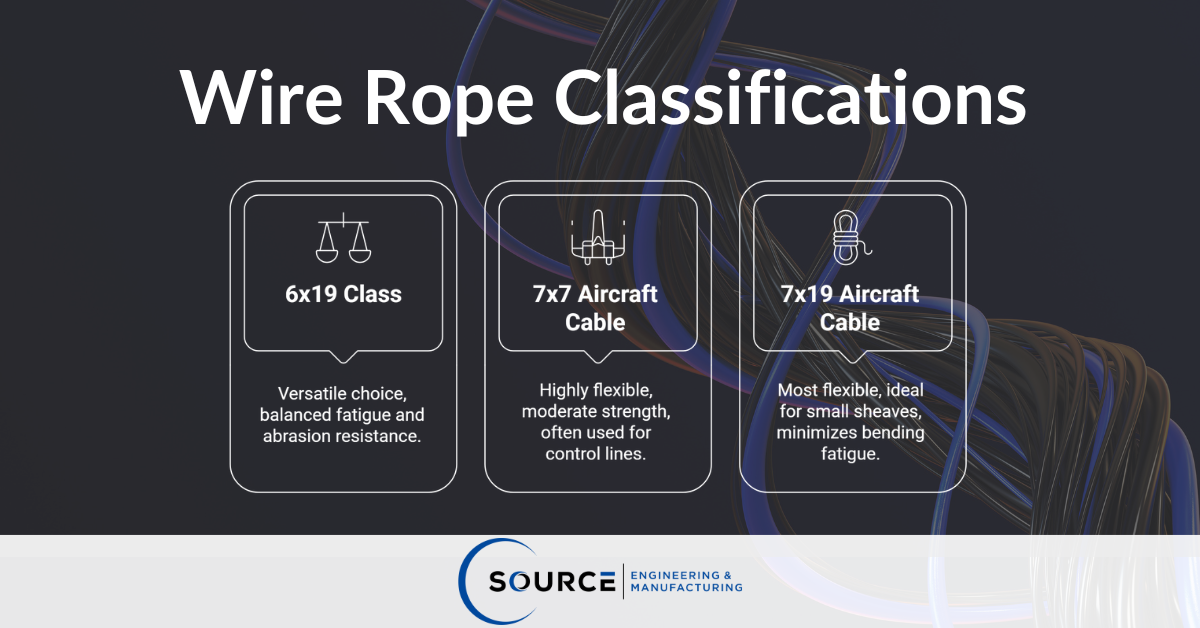

What are the three types of wire rope?

Wire rope is classified by its structural configuration, which defines the balance between tensile strength, flexibility, and abrasion resistance. These basic constructions influence its suitability for various mechanical applications and hybrid assembly designs.

The three primary structural classifications often found in custom assemblies include:

- 6x19 Class: This class is a versatile choice, offering a balanced combination of resistance to fatigue and resistance to abrasion.

- 7x7 (Aircraft Cable): Highly flexible due to its smaller component strands, this construction provides moderate strength and is often specified for control lines.

- 7x19 (Aircraft Cable): This construction is the most flexible of the common types, making it ideal for applications where the rope must run repeatedly over small sheaves or pulleys, minimizing bending fatigue.

Partner with Source Engineering & Manufacturing

If your project demands high-precision Custom cable assemblies, specialized wire harnesses, or both, eliminate the time and risk of searching generic listings. Choose Source Engineering & Manufacturing, the Total Manufacturing Company that specializes in low-volume, high-tech equipment, saving you time and money.

We deliver the technical expertise, speed, and U.S.-based reliability that complex assemblies require. Visit www.sourceeng.com to partner with Source Engineering & Manufacturing on your next project. Request a quote today or call us at 763-745-2833.

.png?width=1584&height=396&name=BANNER%20SOURCE%20(2).png)