Table of Contents

Engineers, procurement leads, and operations managers across critical sectors like defense, medical, and industrial automation consistently seek reliable partners for specialized interconnect solutions. Understanding what custom cable assembly manufacturers provide, why these assemblies matter, how they’re made, and how to choose the right partner is essential for making informed decisions. This resource will clarify these concepts, highlighting the expertise required to deliver high-performance solutions, while also touching upon industrial cable assemblies and wire harness cost.

What is a cable assembly?

A cable assembly is a group of cables or wires organized into a single unit, typically encased in a protective sheath or sleeve, designed to transmit power, data, or signals for a specific application. This integrated unit is distinct from individual wires or off-the-shelf cables because it is engineered with precise specifications, including length, terminations, and environmental resistance. These assemblies are pre-cut, pre-terminated, and often tested to ensure their reliability and performance in the intended operational environment.

The fundamental components of a cable assembly are carefully selected to withstand the demands of its operating conditions, ranging from extreme temperatures and moisture to abrasion and vibration. For instance, a basic assembly involves combining conductors with specific insulation, shielding, and jacketing materials, all chosen to meet stringent performance requirements. This meticulous design ensures that the assembly can transmit signals without interference and maintain structural integrity throughout its lifespan.

Beyond simple bundling, cable assemblies are often overmolded or heavily insulated, providing superior protection against harsh environmental factors that could compromise performance. This robust construction makes them ideal for demanding external applications where exposure to elements is unavoidable. The comprehensive nature of a cable assembly means it arrives as a ready-to-install component, reducing assembly time and potential errors for the end-user.

What is a custom cable?

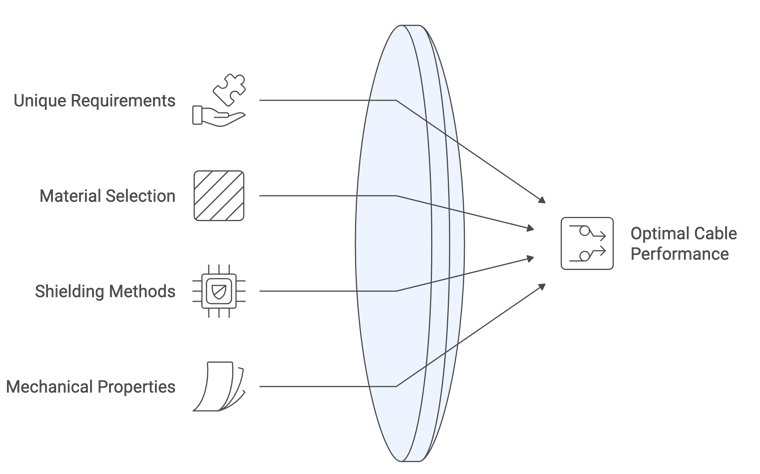

A custom cable is specifically designed and manufactured to meet unique performance, environmental, or spatial requirements that standard, commercially available cables cannot fulfill. These cables are engineered from the ground up to address specific demands related to size, shielding, material composition, or resistance to extreme conditions. Common applications for custom cables span various high-stakes sectors, including aerospace, defense systems, advanced medical devices, and complex industrial automation machinery. For instance, the creation of custom connector holders for wiring harness assembly has been achieved through 3D printing, enabling secure locking of connectors during cable manipulation and simplifying the overall mechanism. This bespoke engineering ensures optimal functionality and longevity for critical equipment.

Developing a custom cable often involves tailoring every aspect, from the gauge and type of conductor to the dielectric material and outer jacket. Engineers specify shielding methods—such as foil, braid, or spiral—to mitigate electromagnetic interference (EMI) or radiofrequency interference (RFI) for sensitive electronics. Material selection also considers flexibility, chemical resistance, UV stability, and flame retardancy to match the exact operational context. These detailed design considerations are crucial, especially for advanced robotic systems that rely on precise and uninterrupted data and power transmission.

The advantages of custom cables extend to meeting specific mechanical properties, such as extreme flexibility for robotic arms with complex motion paths, or rigid durability for fixed installations in industrial plants. Achieving such precise specifications often involves iterative design and testing phases, ensuring that the final product performs flawlessly under anticipated stresses. This level of customization distinguishes a specialty manufacturer from general suppliers, as they can translate intricate application requirements into tangible, high-performance cable solutions.

What is a custom cable used for?

Custom cable applications are integral to systems where precision, compliance with strict standards, and unwavering reliability are non-negotiable. They are deployed in real-world scenarios such as military vehicles, where robust performance in harsh environments is critical, or in intricate robotic systems, where specific data transmission and power requirements must be met without fail.

Despite advances in automation, wiring harness production, a key area for custom cable assemblies, remains a task still completely carried out manually in many instances due to the required precision and dexterity in handling deformable linear objects like wires and cables. This underscores the specialized skill and meticulous attention needed, especially for military cable assembly manufacturers.

Beyond military uses, custom cables are indispensable in medical technology, where consistent performance and biocompatibility are paramount for life-sustaining equipment and diagnostic tools. In industrial automation, they are designed to withstand constant motion, chemical exposure, and temperature fluctuations, ensuring uninterrupted operation of machinery. This includes complex robotic systems that perform assembly operations, which require a variety of cable designs for power, signal, and data transmission.

For instance, in complex robotic systems, failures often stem from calibration or positioning errors, leading to potential damage to the robot or assembly components. Custom cables in these applications must accommodate such demands, supporting advanced sensory systems like tactile and proximity sensors for precise wire positioning and routing, ensuring that robots can handle deformable linear objects with the necessary dexterity. These applications demand a thorough understanding of both the electrical and mechanical requirements, extending to the use of specialized materials and constructions for optimal performance.

What is the difference between a cable assembly and a wire harness?

While often used interchangeably, cable assemblies and wire harnesses exhibit distinct characteristics regarding complexity, environmental protection, and design flexibility. A cable assembly typically bundles multiple individual cables within a single outer jacket or braided sleeve, primarily protecting them from abrasion, moisture, and other environmental factors. They are often designed for specific, harsh environments, resulting in a heavier and more durable product.

This can include specialized shielding against electromagnetic interference or resistance to chemicals and extreme temperatures. In contrast, a wire harness organizes multiple individual wires, sometimes with a few cables, using straps, cable ties, or simple sleeves, aiming to streamline routing and protect against minor abrasions and vibrations. Wire harnesses are generally simpler, lighter, and more flexible, making them suitable for internal applications where severe external conditions are not a concern.

The choice between a cable assembly and a wire harness depends on the application's environmental exposure, flexibility needs, and cost factors, guiding industries to select the most appropriate solution from industrial cable assembly manufacturers. For further clarity, a detailed comparison of cable assembly vs wire harness is available.

The structural differences also dictate their respective manufacturing processes. Cable assemblies often involve more intricate termination methods and require robust outer jackets, which contribute to higher material and labor costs. Wire harnesses, while less protective against extreme conditions, excel in organizing vast numbers of wires into a manageable system, simplifying installation and maintenance within confined spaces. For example, in automotive applications, wire harnesses are critical for routing power and signals throughout a vehicle's electrical system efficiently.

Ultimately, the decision to use a cable assembly or a wire harness comes down to the operational environment and the level of protection required for the conductors. Where ruggedness, long-term durability, and resistance to external elements are paramount, a cable assembly is the preferred solution.

For internal organization, weight reduction, and moderate protection in less aggressive environments, a wire harness offers a practical and often more economical alternative. Experienced custom cable assembly manufacturers understand these distinctions and guide clients in selecting the optimal solution for their specific project.

How do you manufacture a cable?

The manufacturing of custom cable assemblies manufacturers entails a multi-step process that demands precision and strict adherence to rigorous quality standards. It begins with meticulous design, often utilizing CAD data to extract goal pose data for each component, which can be integrated into advanced assembly systems. This digital foundation is crucial for planning the assembly.

The physical process involves carefully selecting appropriate conductors, insulating materials, and shielding, followed by precise cutting, stripping, and crimping of terminals. These prepared components are then meticulously arranged, bundled, and frequently encapsulated within protective jackets or overmolding.

Each stage requires specialized equipment and skilled technicians to ensure optimal performance, particularly when striving for sub-millimeter accuracy. It is important to note that the pose accuracy of commercially available, conventional industrial robots is typically in the range of several millimeters, underscoring the challenge of achieving such high precision without advanced techniques and expert oversight.

For tasks requiring high precision, specialized grippers and control systems are developed. For example, a multi-modal gripper with parallel-jaw elements, electromagnets, and rotary modules can perform various operations like insertion, routing, and threading. These grippers often integrate structural compliance to compensate for robot motion inaccuracies. The entire assembly framework relies on interpreting CAD data for component poses and collision models, with vision systems primarily used for calibration to refine initial estimates.

Advanced methods, such as active compliance control, further compensate for positioning errors by adjusting robot arm trajectories based on force and torque data. This level of integration is what sets leading custom cable assembly manufacturers apart, enabling them to produce complex assemblies for demanding applications.

Is making your own cables worth it?

For specialized applications in industries like defense, medical, or industrial automation, attempting in-house custom cable assembly is not a cost-effective or safe solution. The hidden costs and inherent risks associated with DIY manufacturing typically far outweigh any perceived savings. These include significant investments in specialized tooling, which can run into thousands of dollars for crimpers, strippers, and testing equipment for various connector types.

Furthermore, achieving high-quality, compliant assemblies demands extensive design experience and deep knowledge of specific industry standards. The risks of errors—such as improper termination, inadequate shielding, or incorrect wire gauging—can lead to highly cost system failures, extensive downtime, and even safety hazards, making professional best custom cable assemblies manufacturers a superior choice.

The complexity of wire and cable properties, especially for deformable linear objects (DLOs), further complicates in-house efforts. The "formlessness of the cables entails unknown and inconstant states of the assembly objects," making automation, let alone manual in-house assembly, extremely challenging. Professional manufacturers possess sophisticated equipment and software, such as CAD-based localization and compliance control systems, to effectively handle these variables. They also have established quality control processes, including rigorous testing for electrical continuity, insulation resistance, and mechanical integrity, which are difficult and expensive to replicate in-house.

Moreover, compliance with industry-specific certifications (e.g., ISO, MIL-SPEC) requires specialized knowledge and validated processes that are difficult for internal teams to attain without significant investment and expertise. Inadequate in-house assemblies can lead to product recalls, regulatory fines, and significant reputational damage. Therefore, leveraging the specialized knowledge and infrastructure of professional custom cable assembly manufacturers is almost always the more prudent and economically sound decision for critical applications.

How much does a wire harness cost?

The wire harness cost is influenced by a multitude of factors, resulting in significant variability. Key determinants include the types and quality of materials (conductors, insulation, shielding), the complexity of the design, and the specific connectors and terminals utilized. Any required environmental protections or compliance certifications also impact the overall cost. Labor expenses, which vary considerably by region and skill level, play a substantial role in the final price. Additionally, production volume affects the unit cost, with higher runs often benefiting from economies of scale.

Any specialized testing or custom tooling required for unique designs can also add to the overall expense, impacting the typical pricing ranges discussed in a custom cable assemblies manufacturers.

For example, specialized materials like those used in cryogenic environments place extreme demands on components, often requiring custom designs and high-performance flexure hinges. Such niche applications naturally increase costs due to the need for advanced materials and precise engineering.

The type of connectors, ranging from simple crimp terminals to complex multi-pin industrial or military-grade connectors, also significantly influences the material cost and the labor involved in their termination. Some applications might require tactile sensors and proximity sensors integrated directly into the assembly process, adding to the overall complexity and cost.

Manufacturers also consider the necessary quality assurance and testing procedures when calculating the wire harness cost. Extensive functional testing, pull tests, environmental simulations, and visual inspections are common, particularly for critical applications. These steps, while essential for reliability, contribute to the total manufacturing cost. Understanding these intricate layers of cost drivers enables clients to appreciate the value proposition offered by experienced custom cable assembly manufacturers.

How big is the wire harness market?

The wire harness market is a significant and continuously expanding sector, primarily driven by increasing global electrification and automation across diverse industries. While specific market figures are dynamic, the continuous expansion of sectors such as automotive (especially electric vehicles), industrial machinery, aerospace, and medical devices fuels a steady demand for high-quality, reliable interconnect solutions.

The complexity and demand for precision in these applications only continue to rise. For example, the efficiency of advanced Graphical User Interfaces (GUIs) used in configuring robotic assembly systems can be significant; one study found that a developed GUI allowed participants to complete system configuration 59% faster than manual text editing, taking an average of 5 minutes and 3 seconds compared to 12 minutes and 25 seconds.

This highlights the sophisticated tools and methodologies employed by leading manufacturers to manage complexity and ensure efficiency in producing essential components like wire harnesses and custom cable assemblies.

The strong industrial relevance of wire harness manufacturing means that automation is a primary focus for robotics research, as manual production is labor-intensive despite its repetitive nature. This push for automation is visible in efforts to integrate dual-arm robotic systems and multimodal sensory technologies to handle deformable linear objects like cables and wires. Such systems aim to improve accuracy and reliability, while also ensuring adaptability to different product designs and operational conditions, which is a crucial factor in this growing field.

The market’s growth is also influenced by the increasing demand for advanced functionalities in modern equipment, requiring more sophisticated and compact wiring solutions. This includes trends in smart factories, where flexible and versatile assembly systems are needed to handle increasing product variants with shorter life cycles and fluctuating market conditions. Consequently, the sustained need for high-quality, custom-engineered interconnects positions custom cable assembly manufacturers as indispensable partners in global technological advancement and industrial innovation.

When your application demands precision, reliability, and strict adherence to industry standards, partnering with a specialist in custom cable assemblies is paramount. Source Engineering & Manufacturing is a proven U.S.-based leader, trusted across defense, medical, and industrial sectors for delivering custom solutions with unmatched quality, fast turnaround times, and expert support.

Setting up in-house cable assembly can be complex and costly—covering certifications, compliance, and quality control. At Source Engineering & Manufacturing, these systems are already in place, ensuring reliability and efficiency from day one. Looking for a partner who understands your industry’s toughest demands? Visit www.sourceeng.com and request your custom quote today.

.png?width=1584&height=396&name=BANNER%20SOURCE%20(2).png)