Table of Contents

Choosing the right cable manufacturing partner is critical to ensuring reliable connectivity and long-term performance in any project.. Whether for power transmission or intricate data signals, the company behind the cable considerably impacts performance and longevity. This guide explores the diverse landscape of cable manufacturers, sheds light on their production methods, and offers insights into selecting a supplier that meets specific technical and quality requirements, including a look at the intricate cable manufacturing process and key considerations for data cable manufacturers.

Who makes electric cables?

Electric cable manufacturers generally fall into three main categories, each addressing distinct market needs.. Bulk cable producers focus on high-volume, standardized cables used in construction, utilities, and general industrial applications, leveraging economies of scale and broad distribution. OEM-focused manufacturers design and produce cables tailored for specific original equipment, integrating closely with product development teams to meet unique specifications.

The third segment comprises custom cable providers, who specialize in niche, high-performance sectors. These companies, like Source Engineering & Manufacturing, serve industries with demanding requirements, such as automation and semiconductor manufacturing. They often work with low-volume, high-tech equipment and small-to-medium production run lot sizes.

The complexity of modern assembly operations, particularly with deformable linear objects like cables and wires, highlights the need for specialized manufacturing expertise. While the production of wiring harnesses remains largely a manual task—requiring intricate routing and bundling of multiple wires—the increasing demand for them makes robotic automation a significant focus. By contrast, cable assemblies are engineered as complete, ruggedized solutions for durability in harsh environments.

This underscores the critical need for precisely engineered cables that can withstand complex handling and integration.

What are the four types of data cables?

Data cable manufacturers typically focus on four primary types: twisted pair, coaxial, fiber optic, and USB cables. Each type offers distinct advantages for various data transmission needs. Twisted pair cables, commonly used in Ethernet networks and telecommunications, reduce electromagnetic interference through their twisted wire pairs. Coaxial cables, historically used for video and internet connections, offer good shielding and higher bandwidth over longer distances than twisted pair.

Fiber optic cables transmit data as light signals, providing very high speeds, immense bandwidth, and immunity to electromagnetic interference, making them ideal for long-distance and high-security applications. USB cables provide universal connectivity for a wide range of devices, delivering both data and power. Custom variants of these cables are prevalent in specialized applications. For instance, ruggedized coaxial cables are engineered for harsh environments, while shielded twisted pair cables offer enhanced EMI protection critical in industrial settings.

Common Data Cable Types

|

Cable Type |

Primary Use |

Key Feature |

Custom Variant Example |

|

Twisted Pair |

Ethernet, telecommunications |

Reduces electromagnetic interference |

Shielded for industrial EMI protection |

|

Coaxial |

Video, internet |

Shielded, high bandwidth for distance |

Ruggedized for harsh environments |

|

Fiber Optic |

High-speed data, long distance |

Light signals are immune to EMI |

Armored for outdoor, industrial use |

|

USB |

Device connectivity |

Universal, power, and data |

Medical-grade, custom length & jacket |

What is the manufacturing process for cables?

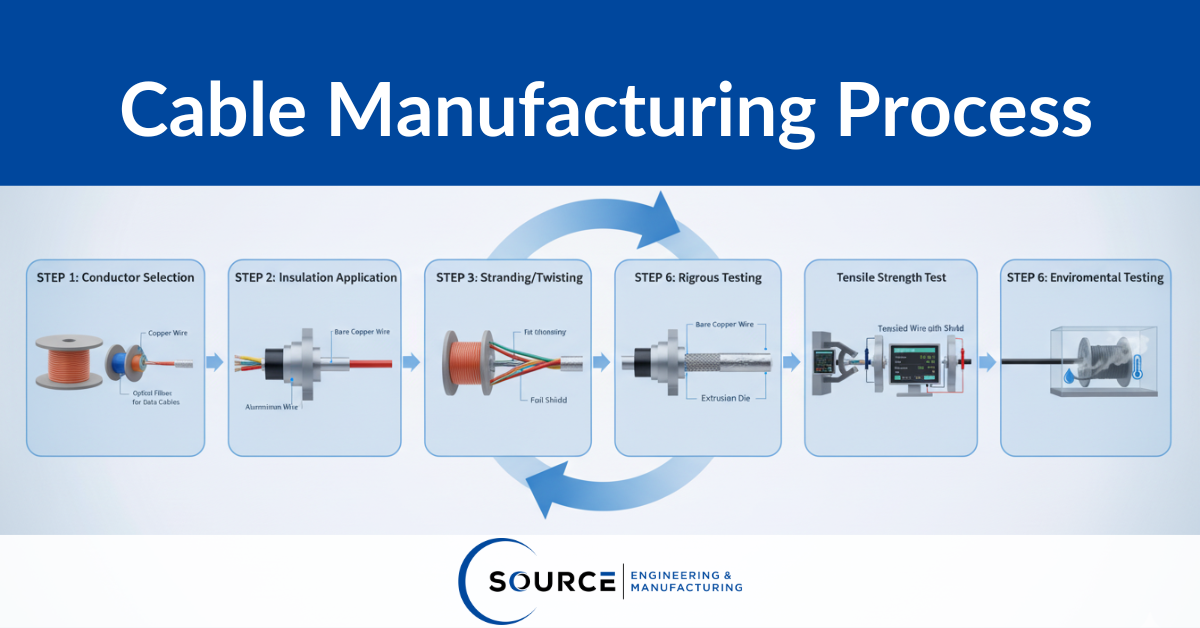

Cable manufacturing transforms raw materials into advanced electrical and data transmission lines through a series of precise, critical steps. It typically begins with conductor selection, often copper or aluminum, or specialized optical fibers for data cables. Following this, insulation is applied through extrusion, covering each conductor with a protective polymer layer. For multi-conductor cables, individual wires are then stranded or twisted together, a step vital for flexibility and to mitigate electromagnetic interference.

Shielding, using materials like braided wire or foil, is added to protect against external interference, particularly important for data cables. The entire assembly then receives an outer protective layer, known as jacketing, which safeguards against mechanical damage, moisture, and environmental factors.

Throughout production, rigorous testing is conducted to ensure electrical, mechanical, and environmental performance meets specifications. Robotic assembly systems demonstrate the precision required in later stages, where grippers handle components with exact grasp type, effort, and offset commands.

These precise post-manufacturing operations rely on consistent cable quality. The challenge in automating cable assembly, which involves handling flexible, jacketed cables—lies in the unknown and inconsistent states of these deformable components. This is distinct from wire harness assembly, where the challenge is manually arranging and securing multiple individual wires. This emphasizes the importance of a meticulously controlled manufacturing process to minimize variations.

What makes a good cable manufacturer?

A good cable manufacturers distinguishes itself through a commitment to quality, adaptability, and comprehensive support throughout a product's lifecycle. Rigorous testing standards are paramount, encompassing electrical continuity, mechanical strength, and performance under environmental stresses. Customization capabilities are essential for industries with unique or evolving needs. Manufacturers should offer tailored solutions, especially for low-volume and high-performance applications.

Certifications such as UL (Underwriters Laboratories), MIL-SPEC (military specifications), and ISO 9001 demonstrate adherence to industry and quality management standards. Supply chain resilience and transparency are increasingly important, ensuring consistent material flow and reliability. Emphasizing U.S.-based production often provides advantages in quality control, communication, and responsiveness.

Manufacturers should also offer responsive engineering support, collaborating closely with clients from design through production. This holistic approach ensures not only the delivery of a superior product but also a partnership that contributes to overall project success.

Conclusion

Selecting the right cable manufacturing partner is pivotal for projects demanding high performance and precision. Companies like Source Engineering & Manufacturing stand out by combining technical expertise with a commitment to custom solutions. Understanding the nuanced requirements for different cable types, from electrical to advanced data options, and appreciating the meticulous manufacturing processes involved ensures optimal connectivity.

Looking for a cable partner who builds more than just wire? Source Engineering & Manufacturing is a leader in custom cable manufacturing, serving industries where performance and precision are critical. Reach out today at www.sourceeng.com to request a quote or discuss your project.

.png?width=1584&height=396&name=BANNER%20SOURCE%20(2).png)