Table of Contents

In modern industries, standard cable solutions often fall short. This article explores custom wire cables, defining their characteristics, diverse applications, and manufacturing processes. We will explain how these specialized solutions differ from wire rope and other variants, providing valuable insights for technical procurement teams, engineers, and commercial buyers seeking custom cable suppliers. Understanding custom cable manufacturing is essential, as is a clear grasp of factors influencing wire harness cost.

What are custom cables?

Custom wire cables or custom cables are specially designed cable systems, offering a precise alternative to mass-produced, off-the-shelf cable stock, engineered for optimal performance in demanding applications. As manufacturing trends shift, adaptable cable solutions are essential for agile automation systems. Standard cables often lack specific properties needed for extreme temperatures, corrosive chemicals, or intense electromagnetic interference.

Custom wire cables are fabricated with meticulous attention to material selection, conductor gauge, insulation, and shielding to precisely match challenging conditions. For example, high position accuracy in automated assembly, with tolerances in the submillimeter range (for gripping and placement), is only achievable with precisely engineered components. This precision, also observed in 3D models, highlights the need for tailored solutions that reliably integrate into complex machinery, especially as robotic system flexibility becomes more critical in smaller production batches.

What are custom cables used for?

Custom wire cables are indispensable across a wide array of high-stakes industries, powering everything from advanced robotics and transportation to sophisticated medical diagnostics and military-grade communications. Their utility stems from their ability to offer unparalleled flexibility in terms of voltage, shielding, jacketing, and overall configuration.

In robotics and industrial automation, where there is a rising demand for agile automation systems, custom wire cables ensure the reliable operation of complex machinery. These cables power robot manipulators, transmit critical sensor data, and facilitate intricate assembly tasks.

For example, in flexible robotic assembly systems, robust and adaptable cables are vital for operations like insertion, routing, or threading, which demand a variety of motions and precise control. The development of specialized robotic systems for tasks like wiring harness manufacturing further emphasizes this need, as they rely on custom cables for power and signal integrity.

For the medical sector, custom wire cables manufacturers produce solutions that are critical for devices like diagnostic imaging machines, surgical robots, and patient monitoring systems. These applications require bio-compatible materials, sterile designs, and uncompromised signal integrity to ensure patient safety and accurate data transmission. In transportation, particularly in the rapidly evolving electric vehicle (EV) market, custom wire cables suppliers develop high-voltage power cables, battery management system (BMS) harnesses, and communication lines that must withstand vibration, extreme temperatures, and high current loads.

The complex wiring harnesses in modern vehicles, for instance, exhibit great variability in design, making the use of automatic machines unprofitable for standard solutions. In military and aerospace, where operational reliability in harsh environments is paramount, custom cables are engineered to resist extreme temperatures, moisture, abrasion, and electromagnetic interference, ensuring uninterrupted communication and control in critical defense systems.

How to manufacture a wire harness?

Manufacturing a wire harness involves a sequence of precise operations: cutting wires to specific lengths, stripping their ends, crimping terminals onto them, bundling the wires according to a schematic, and finally assembling connectors and protective coverings. This intricate process culminates in a robust, organized assembly that integrates numerous electrical circuits into a single and cohesive unit.

A wire harness is often preferred over a multi-core cable when an application requires specific branching, varied wire types, or numerous connection points that would be impractical or unmanageable with a single, thick cable. The inherent complexity and variability in the design of wiring harnesses necessitate specialized manufacturing approaches, often making manual production the norm due to the difficulty of automating such tasks profitably.

However, recent advancements in automation are transforming wire harness manufacturing. Robotic assembly systems, particularly dual-arm configurations, are increasingly employed to enhance accuracy, repeatability, and efficiency.

These systems utilize specialized end-effectors, such as custom-made grippers equipped with tactile and proximity sensors, for tasks like pick and place of the branches; routing of the cables; and spot taping. Multimodal sensing systems provide robots with enhanced capabilities for precision and safe interaction with deformable linear objects (DLOs) like wires.

For example, a pulling operation on a wire harness reveals that slippage can occur when the applied force reaches around 20 to 30 N, highlighting the need for precise force control in automated handling. Such advanced techniques allow best custom wire cables manufacturers to adapt to various conditions and produce different types of wiring harnesses, addressing the challenge of product variability. The ultimate goal is to increase productivity and improve operator working conditions in what has historically been a strenuous manual task.

How much does a wire harness cost?

The wire harness cost can vary considerably, influenced by a multitude of factors, ranging from raw material specifications to manufacturing complexity and regulatory compliance. Custom designs, while initially potentially higher in cost than off-the-shelf alternatives, typically offer a substantial return on investment (ROI) through enhanced performance, superior longevity, and reduced operational disruptions. Precision-built harnesses eliminate the need for costly rework, minimize downtime due to failures, and ensure compliance with stringent industry standards, making them a strategically sound choice for technical applications.

Key factors influencing wire harness cost include:

- Wire Gauge and Type: The thickness and material (e.g., copper, aluminum) of the individual wires directly impact cost. Specialty wires, such as shielded or high-temperature variants, increase prices.

- Insulation and Jacketing Materials: The type of insulation (e.g., PVC, silicone, PTFE) and outer jacketing (e.g., urethane, braided sleeving) selected for environmental protection, chemical resistance, or flexibility notably affects cost.

- Connector Complexity: The number, type, and brand of connectors used, including their pin count and locking mechanisms, are major cost drivers.

- Assembly Complexity: The intricacy of the harness design, including branching points, routing paths, and the number of individual connections, influences labor and automation costs.

- Testing and Certifications: Rigorous testing protocols (e.g., electrical, continuity, pull-force) and compliance with industry-specific standards (e.g., automotive, medical, military) add to the overall cost.

Investing in the best custom wire cables can reduce tied capital and avoid opportunity costs by scaling production efficiently, particularly within agile manufacturing systems that adapt to fluctuating demands. This approach ensures that the initial investment translates into long-term operational savings and system reliability, rather than incurring ongoing expenses from failures or inefficiencies associated with generic solutions.

How to coil electrical wire?

Properly coiling electrical wire is important for maintaining its integrity, preventing damage, and ensuring ease of storage, transport, and maintenance. When coiling manually, begin by creating a loose, natural loop without kinks, allowing the wire to dictate its own curve. To prevent tangles, alternate the direction of each subsequent loop, ensuring a smooth, figure-eight pattern. Always avoid tight bends or sharp creases, as these can stress the conductors and insulation, leading to potential electrical failure. Secure the coiled wire with a soft tie, such as a hook-and-loop strap, rather than electrical tape or zip ties, which can bind too tightly and damage the cable.

Coiled cables are often preferred in applications requiring frequent extension and retraction, like medical equipment or portable power tools, due to their spring-like flexibility. Straight cables are more common for fixed installations where aesthetics and minimal interference are priorities. The inherent flexibility and uncertain deformation of cables during handling make them particularly complex to manage, requiring specialized methods even for basic tasks like coiling. Sophisticated robotic systems that handle cables often employ a custom gripper interface, which accepts grasp type, effort, and offset commands, demonstrating the precise manipulation needed for these materials. This level of control is essential to prevent entanglement or damage, which can lead to the failure of the entire assembly process.

How big is the wire harness market?

The wire harness market is a substantial and growing sector, driven by increasing demand across various high-tech applications. Growth projections indicate a continuous expansion, particularly fueled by innovations in electric vehicles, automation, and defense industries. The automotive sector, in particular, remains a dominant force, with the complex electrical systems in modern cars requiring increasingly sophisticated and numerous harnesses.

The global push towards electric mobility is a significant catalyst for market expansion. Projections from 2021 aimed for one million electric cars to be on the roads by the end of 2022, a clear indicator of the rapid expansion in this segment that fuels demand for advanced wiring solutions. This surge in demand makes manual production increasingly uneconomical, necessitating advanced, automated assembly solutions for wire harnesses. Automation, encompassing industrial robotics and smart manufacturing systems, relies heavily on complex wire harnesses for power and data transmission. These systems require reliable, high-performance cabling to ensure operational efficiency and safety. The defense sector also contributes considerably to market growth, with a constant need for rugged, custom-designed wire harnesses that can withstand extreme conditions and meet stringent military specifications. The overall trend in manufacturing emphasizes greater process autonomy and flexibility, which in turn elevates the importance and market size of reliable wire harness solutions.

Is there a difference between wire rope and cable?

A fundamental distinction exists between wire rope and cable, primarily due to their construction, primary function, and intended applications. While both are composed of multiple strands of wire, their design principles diverge meaningfully.

Wire rope is generally designed for mechanical applications, emphasizing tensile strength, load-bearing capacity, and flexibility under mechanical stress. It's constructed from metal wire strands twisted around a core to withstand heavy loads, pulling, and hoisting, commonly used in cranes or rigging. Conversely, a cable, particularly custom wire cables, is predominantly designed for electrical applications, focusing on transmitting power or signals. These consist of insulated conductors within a protective jacket, prioritizing electrical properties.

This distinction is vital for engineers and procurement teams, especially when sourcing custom wire rope assemblies for heavy-duty mechanical systems versus electrical cables for precision electronics.

To further clarify, here's a simple comparison:

|

Feature |

Wire Rope |

Cable (Electrical) |

|

Primary Function |

Mechanical (lifting, pulling, support) |

Electrical (power, signal transmission) |

|

Core Purpose |

Tensile strength, load bearing |

Conductivity, insulation, shielding |

|

Typical Materials |

Steel, stainless steel, high-strength alloys |

Copper, aluminum (conductors); PVC, PTFE (insulation) |

|

Common Uses |

Cranes, elevators, rigging |

Electronics, power grids, data networks |

What are the types of wire rope?

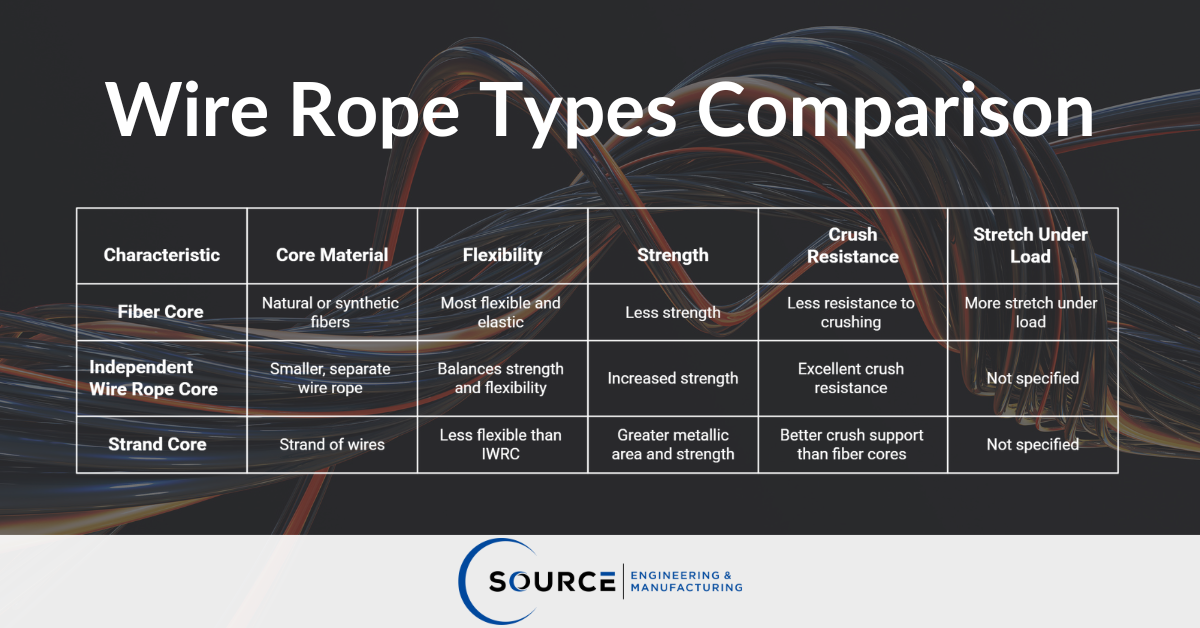

Wire rope is broadly categorized by its core construction, which greatly impacts its flexibility, strength, and resistance to crushing. These core types are vital for determining suitability for specific mechanical applications:

-

Fiber Core (FC): Uses natural or synthetic fibers (e.g., polypropylene, sisal) as its central core. FC wire rope is the most flexible and elastic, suitable for applications requiring frequent bending over sheaves. It offers less resistance to crushing and more stretch under load compared to metallic cores, generally used for lighter-duty tasks or when maximum flexibility is paramount.

-

Independent Wire Rope Core (IWRC): Consists of a separate, smaller wire rope serving as the main rope's core. This construction provides excellent support for outer strands, notably increasing the wire rope's strength, crush resistance, and durability. It balances strength and flexibility, making it a popular, versatile choice for many industrial applications, including cranes, excavators, and drilling lines.

-

Strand Core (WSC): A strand of wires (similar to outer strands but without an IWRC's internal rope) acts as the center. A WSC offers greater metallic area and strength than an FC but is generally less flexible than an IWRC. It provides better crush support than fiber cores, offering an intermediate option between FC and IWRC in performance characteristics.

These distinctions are vital for engineers and procurement teams selecting the appropriate wire rope for specific mechanical tasks, ensuring safety, optimal performance, and longevity.

Conclusion:

Custom wire cables and wire harnesses are indispensable for modern industrial applications where standard solutions are insufficient, providing the precision and adaptability required for robotics, medical, and military systems. Understanding the distinction between custom wire cables for electrical functions and wire rope for mechanical strength is vital. Investing in these specialized solutions delivers significant long-term value, enhancing efficiency and reliability in evolving manufacturing environments.

Need a custom solution for your next cable or assembly project? Source Engineering & Manufacturing builds high-performance custom wire cables and harnesses for industrial, medical, and military applications, delivering precision, durability, and speed. Request a quote or explore custom options at www.sourceeng.com .

.png?width=1584&height=396&name=BANNER%20SOURCE%20(2).png)