What is a Cable Assembly?

Written by Source Engineering | read

Table of Contents

A cable assembly is a specialized product, essential to many industries, that combines multiple electrical wires or cables into a single, organized unit. These assemblies are carefully engineered to reliably transmit power, data, or signals within complex systems. They are more than just bundled wires; they are critical, custom-built solutions designed to meet strict performance and environmental requirements.

Understanding the role of cable assembly manufacturers and the distinctions between components, such as a cable assembly and a wire harness, is vital for optimizing system performance and ensuring product reliability. Source Engineering & Manufacturing, for example, specializes in producing custom cable assemblies and wire harnesses for low-volume, high-tech equipment and small to medium production runs in the automation and semiconductor industries.

What is a cable assembly in electrical?

In electrical contexts, a cable assembly refers to a group of wires, along with their connectors, insulation, and protective sheathing, combined into a single, integrated unit. This bundled design ensures efficient and organized transmission of electrical power, signals, or data. Unlike individual wires, an assembly is a complete, ready-to-install component, precisely configured for a specific application.

Typical elements include conductors such as copper or fiber optic, terminal connectors for device interfacing, and external jacketing or braiding to shield against moisture, abrasion, or electromagnetic interference. Cable assembly manufacturers create these components for specific functions, integrating them into a cohesive system that performs reliably even under harsh conditions. The intricate nature of these products demands a high level of skill and precision during production.

What is a cable assembly used for?

Cable assemblies are essential for delivering tailored connectivity solutions across a wide range of demanding industries. They are widely used in critical applications such as medical devices, aerospace systems, automotive electronics, telecommunications infrastructure, and military equipment.

Each assembly is custom-designed to withstand specific operational environments and mechanical stresses, including high temperatures, vibration, moisture, and electromagnetic interference. For example, in advanced manufacturing, cable assemblies are crucial for agile automation systems that must quickly adapt to changing task requirements.

Their design must account for the mechanical properties and precise routing required for specialized machinery. The unique design for each application often requires specific considerations, including that its cable assembly has code for international trade and classification.

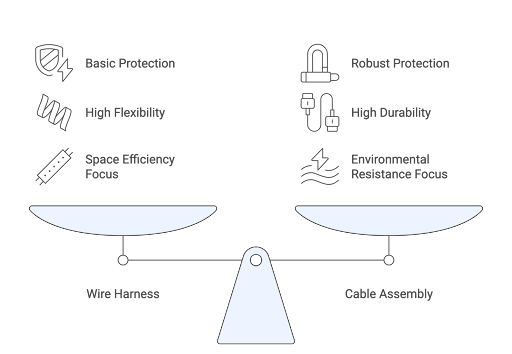

What is the difference between a cable assembly and a wire harness?

Although often used interchangeably, a cable assembly and a wire harness are distinct. A wire harness is primarily designed to organize multiple wires and cables into a neat, easily installable package, usually for routing through confined spaces and offering basic protection against abrasion.

Its main purpose is organization and space efficiency, with individual wires often exposed or lightly wrapped, making it flexible for routing through chassis or panels. For example, in a robotics competition, the wire routing task involved a USB cable routed around two vertical pins and through two brackets before being plugged into its slot, demonstrating the organizational complexity typical of harnesses.

By contrast, a cable assembly is generally more robust and enclosed, built for harsher environments and specific electrical or data transmission needs. They usually feature heavy-duty sheathing, specialized connectors, and undergo rigorous testing to ensure durability and performance under defined mechanical stresses or environmental conditions. This distinction is critical in applications where environmental resistance, signal integrity, or strong mechanical protection are essential.

Automated production of wire harnesses, which involves handling flexible linear objects like cables, remains a challenge, with many operations still performed manually due to process complexity and product variability.

What is the cable assembly process?

The cable assembly process is a comprehensive manufacturing sequence that transforms raw wires and components into a high-performance, application-specific solution. It begins with a detailed design stage, where engineers define precise specifications based on the client’s application and environmental needs.

This is often followed by prototyping, which allows for iterative refinement before full production. Subsequent steps include accurate wire cutting and stripping, crimping specialized connectors onto individual wires, and precise soldering to ensure strong electrical connections.

Once prepared, the wires are bundled, typically with protective coverings such as insulation, braiding, or jacketing, to create the final assembly. This bundling enhances organization, protects against physical damage, and can provide electromagnetic shielding.

Automated systems are increasingly part of this stage; new robot installations in manufacturing rose by an average of 19% annually from 2013 to 2018, boosting efficiency and precision. The final critical step is rigorous testing, where assemblies are verified for electrical continuity, insulation resistance, and mechanical integrity, often following industry standards.

Source Engineering & Manufacturing incorporates quality assurance throughout the entire cable assembly process to deliver reliable products that meet exact application requirements.

Final Thoughts:

Understanding the definition, applications, and manufacturing of a cable assembly highlights its vital role as a custom-engineered solution for dependable power, data, and signal transmission across diverse industrial needs. Source Engineering & Manufacturing delivers specialized cable assemblies designed for harsh environments, high-speed data, and power systems.

Instead of managing the complexity of in-house cable assembly—with certifications, UL and ISO compliance, and rigorous quality checks—partner with experts who already have these systems in place. Ready for a solution built around your exact needs? Visit www.sourceeng.com and connect with us to start your custom cable assembly project today.

.png?width=1584&height=396&name=BANNER%20SOURCE%20(2).png)

.png?width=400&name=Source%20Engineering%20Blog%20(4).png)