Table of Contents

Currently, the advanced technology and specialized equipment of custom cable manufacturing are the foundation of precise, reliable connectivity solutions. Unlike generic cables that serve broad applications, custom cables are specifically engineered to meet the performance, durability, and environmental requirements of complex systems. These assemblies can transmit power, carry sensitive data, or withstand demanding mechanical forces—making them essential across industries from aerospace to healthcare.

One of the most important advantages of custom cables is their ability to integrate seamlessly into systems where failure is not an option. A medical imaging device, for example, cannot afford interference or power fluctuations, while defense systems require cabling that remains reliable under extreme environmental stress. Partnering with professional custom cable assemblies manufacturers gives engineers and procurement teams access to specialized expertise in design, materials, and compliance. These partnerships ensure that every cable assembly is built with strict attention to safety standards and performance goals.

This article explores the fundamentals of custom cable technology: what makes a cable “custom”, the variety of applications they serve, the detailed steps in the manufacturing process, and the raw materials that determine performance. It will also highlight the significant advantages of professional manufacturing over DIY approaches, particularly in terms of cost-effectiveness, reliability, and compliance. For operations leaders and product designers, understanding the capabilities of custom cable manufacturing is essential for making informed decisions that directly impact system performance and long-term success.

What is a custom cable?

A custom cable manufacturing solution is not simply a variation of a standard wire; it is a purpose-built product engineered to meet exact specifications for performance, safety, and durability. While off-the-shelf cables are designed for mass markets and general applications, they rarely align with the unique requirements of industries such as medical technology, aerospace, defense, or industrial automation. In contrast, a custom cable is designed from the ground up to serve a specific function, whether that involves carrying precise signals, withstanding high-voltage power or enduring harsh environmental conditions.

The difference lies in the details. Custom cables can be tailored with specific conductor materials, insulation thickness, shielding methods, or connector configurations to ensure they meet both technical and regulatory requirements. For example, a standard cable might transmit power successfully, but in an environment with constant vibration or electromagnetic interference, only a custom-built solution can maintain reliability and safety. Engineers can also specify jacket materials resistant to chemicals or extreme temperatures, ensuring the cable performs consistently in its operating environment.

This flexibility transforms cables from simple conductors into highly specialized system components. They become integral parts of the larger design, allowing equipment to operate with precision and minimizing the risk of downtime. By differentiating between mass-produced, off-the-shelf options and truly engineered solutions, businesses gain a clear understanding of why custom cables are indispensable for mission-critical applications. In essence, custom cable manufacturing provides the assurance that every conductor, shield, and connector is optimized for performance, compliance, and long-term reliability.

What is a custom cable used for?

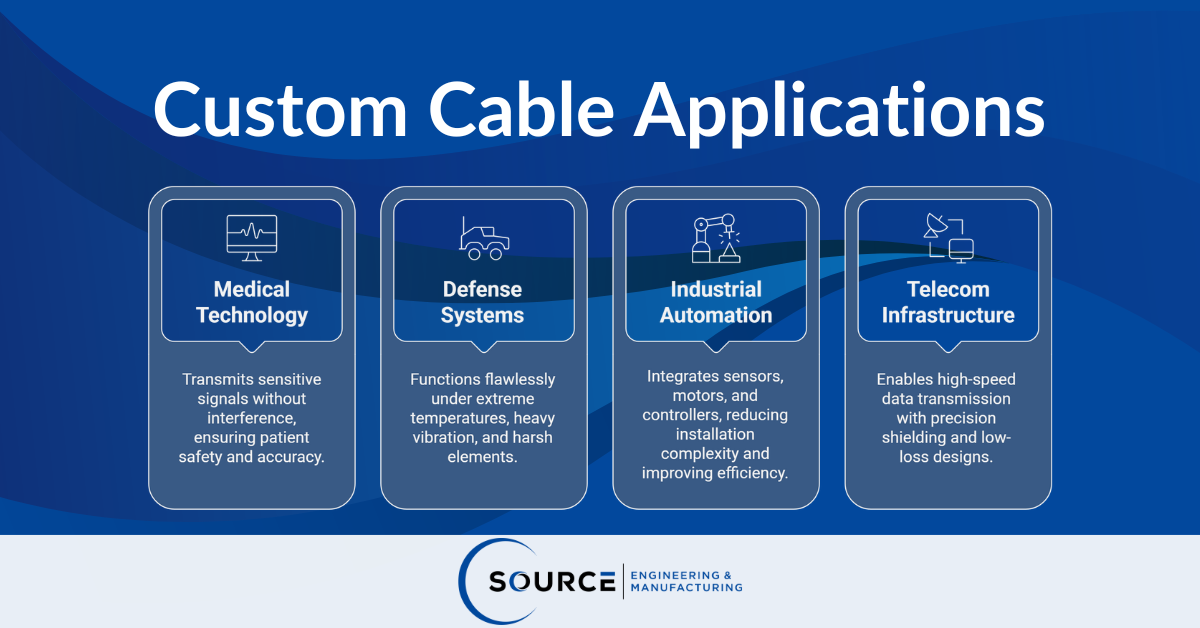

Custom cable manufacturing products play a vital role in industries where reliability, precision, and adaptability are non-negotiable. Off-the-shelf cables may work for basic connections, but advanced sectors demand assemblies that can meet unique technical and environmental conditions. Medical technology is a prime example: diagnostic and treatment devices require cables that transmit sensitive signals without interference, ensuring patient safety and accuracy of results. In defense systems, cables must function flawlessly under extreme temperatures, heavy vibration, and exposure to harsh elements—conditions where standard products would quickly fail.

Industrial automation is another sector heavily dependent on customized solutions. Complex machinery often integrates sensors, motors, and controllers that require hybrid cables capable of transmitting both power and data simultaneously. These assemblies reduce installation complexity, save space, and improve efficiency. Similarly, telecom infrastructure relies on specialized cabling for high-speed data transmission, where precision shielding and low-loss designs are essential to maintain network stability.

A key strength of custom cables is their flexibility in design. Engineers can define conductor size, insulation type, shielding method, and connector configuration to meet specific standards, whether they involve medical safety certifications, military specifications, or global telecom compliance. This adaptability ensures seamless integration into highly specialized systems without the compromises often associated with generic solutions.

By enabling mission-critical performance in demanding environments, custom cable manufacturing products provide industries with the confidence that their systems will remain dependable. They are not just wires, but engineered components that safeguard uptime, enhance efficiency, and support innovation.

How to manufacture a cable?

The process of making a cable is a balance between precision engineering and efficient production. Most custom cable manufacturing companies follow a series of core stages: wire drawing, insulating, cabling, jacketing, and rigorous testing. Wire drawing begins by pulling raw metal, such as copper or aluminum, through progressively smaller dies until the correct gauge is achieved.

This is followed by insulation, where materials like PVC or polyethylene are extruded onto the conductors to ensure electrical safety and performance. Once insulated, multiple wires may be twisted together in the cabling stage, forming the functional core of the assembly. Shielding is often applied at this step to minimize electromagnetic interference, especially for high-frequency data or sensitive signal cables. After that, an outer jacket is extruded to protect the assembly from environmental stressors such as heat, chemicals, or abrasion. Finally, every product undergoes extensive testing for continuity, durability, and compliance with industry standards before it leaves the factory.

Many of these steps can be automated for efficiency, but complex designs or specialized harnesses often require skilled manual labor. For example, intricate wiring harnesses in aerospace or medical devices may demand hand assembly to ensure precise routing and secure connector integration. Robotic systems are increasingly used to complement this process, particularly for tasks like taping or terminal crimping. This combination of human expertise and automation is what defines a reliable cable manufacturing process, ensuring that every assembly meets exact specifications for performance and durability.

What is the raw material for cable manufacturing?

The foundation of any cable lies in the materials selected for its construction, and these choices determine performance, flexibility, and overall cost. Conductors are the starting point, typically made of copper or aluminum. Copper is still the gold standard thanks to its excellent conductivity and long-term reliability, while aluminum offers a lighter and more economical option, especially in large-scale power transmission.

Insulation and jacketing materials provide protection and adaptability. Thermoplastics like PVC and polyethylene are commonly used for their flexibility and affordability, making them suitable for general-purpose applications. Thermosets, by contrast, are more resistant to heat, abrasion, and chemicals, which is essential for cables used in industrial automation or defense environments. For highly specialized systems, advanced polymers such as fluoropolymers may be incorporated to ensure stability under extreme temperatures or exposure to harsh chemicals.

Shielding layers form another critical component. Foil or braided shielding is added to block electromagnetic interference, ensuring signal integrity in applications like medical devices or telecommunications. In high-noise or vibration-heavy environments, engineers may employ double shielding to provide maximum protection.

Understanding how each raw material impacts performance is essential. A low-cost plastic jacket may suffice in consumer electronics, but in aerospace or healthcare, flame-retardant, biocompatible, or chemical-resistant materials may be mandatory. For engineers seeking deeper technical insights, resources such as an electrical wire manufacturing process provide valuable details into how these materials are selected and applied. Ultimately, thoughtful material selection extends service life, reduces downtime, and ensures compliance with stringent industry standards.

What is the manufacturing process for cables?

The manufacturing process for cables is a carefully structured sequence of steps that transforms raw materials into durable, high-performance connectivity solutions. It begins with wire drawing, where copper or aluminum rods are pulled through a series of progressively smaller dies until they reach the desired gauge. Next comes extrusion, where insulating material—such as PVC, polyethylene, or advanced polymers—is applied to coat each conductor, ensuring electrical safety and stability.

Once insulated, conductors may be twisted together (cabling) to form pairs or bundles, a step that reduces electromagnetic interference and improves mechanical strength. Shielding is then added, using foil or braided wire, to protect the cable from external noise. After shielding, the entire assembly is encased in an outer jacket that resists heat, abrasion, and environmental stress

Throughout these stages, drawing towers, extruders, and braiding machines keep production consistent. A modern Cable manufacturing Machine integrates these processes with exacting control, guaranteeing uniformity across production runs. However, some specialized designs, such as complex wiring harnesses, may still require skilled manual labor to achieve perfect assembly.

The final stage is rigorous testing. Every cable is evaluated for conductivity, insulation resistance, durability, and compliance with industry-specific standards. This part of the cable manufacturing process is critical because it verifies that the assembly performs exactly as designed under real-world conditions. Tests can reveal weaknesses in insulation, shielding, or connectors before the product is deployed, reducing the risk of failure once in operation. By combining advanced machinery with strict quality control, manufacturers deliver cables that meet precise specifications, ensuring safety and long-term performance across industries.

How are cables created?

Cables are created through a multi-stage process that blends material science, engineering, and precision manufacturing. At the most basic level, the process begins with forming conductors from copper or aluminum, followed by insulating them with protective coatings to ensure electrical safety. These insulated wires are then bundled together, shielded to minimize electromagnetic interference, and finally encased in a durable outer jacket that protects against environmental stress. This layered process turns raw materials into advanced connectivity solutions, capable of carrying power, data, or signals with high reliability.

While the fundamental stages are similar across most types of cables, the level of customization varies considerably. A simple consumer-grade cable may be produced quickly in high volumes using automated systems, whereas a complex hybrid assembly for aerospace or medical devices requires careful engineering and manual integration. Timelines reflect this: prototyping a new design may take weeks as engineers refine specifications and validate performance, but once finalized, large-scale production can be scaled efficiently with automated systems.

What makes this process unique in custom cable manufacturing is the focus on tailoring every layer of the design to the client’s requirements. From choosing conductor materials to designing specialized shielding and connectors, each decision directly impacts performance, compliance, and cost. Source Engineering reinforces this process with end-to-end capabilities, guiding clients from initial concept through prototyping and into full production. The result is a cabling solution that is not only functional but also engineered for long-term reliability and industry compliance.

Can you make custom HDMI cables?

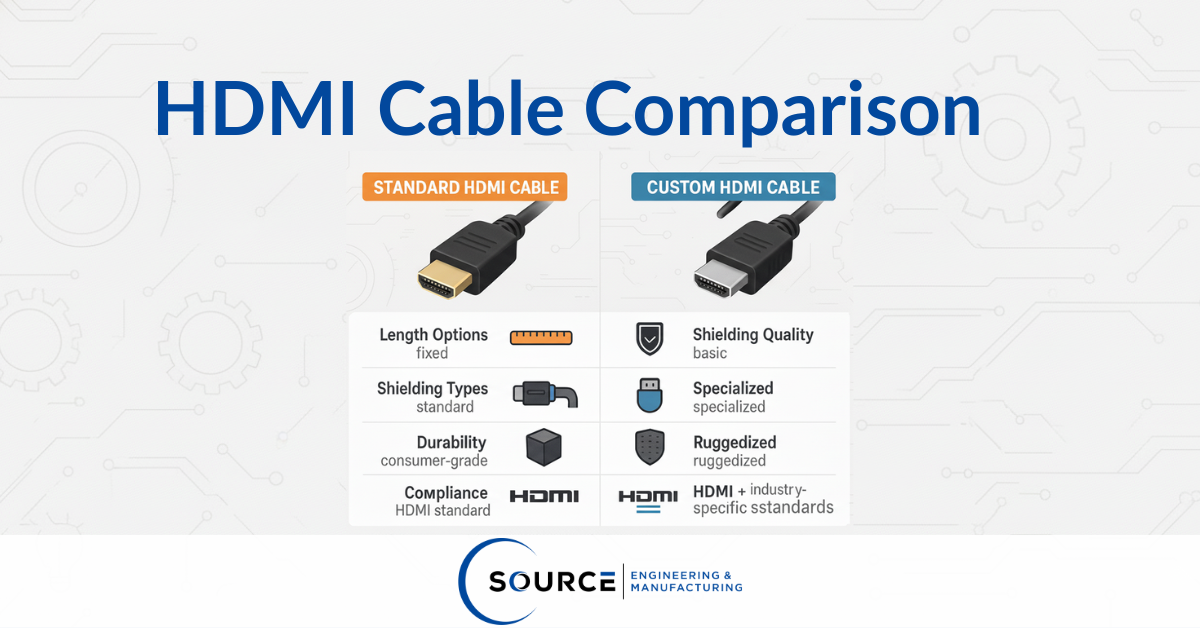

Custom HDMI cables can be designed and manufactured to meet the unique requirements of specialized audiovisual setups, kiosks, control systems, or digital signage. Unlike mass-produced HDMI cables, custom designs let engineers specify length, durability, connector type, and shielding based on the environment where they will be installed.

One of the most critical factors in HDMI cable design is shielding, since high-frequency data must remain stable over distance, and poorly shielded cables are prone to signal loss or interference.

To ensure reliability, safety, and compliance, these cables should always be manufactured and handled by trained professionals with the expertise to select the right conductor materials, insulation types, and jacket compositions for optimal performance. All custom HDMI solutions must comply with HDMI standards, guaranteeing interoperability and reliable data transfer across devices.

To illustrate the differences between standard and custom HDMI options:

|

Feature |

Standard HDMI Cable |

Custom HDMI Cable |

|

Length Options |

Fixed, limited |

Tailored to exact installation needs |

|

Shielding Quality |

Basic |

Enhanced shielding to reduce interference |

|

Connector Types |

Standard only |

Specialized connectors for unique hardware |

|

Durability |

Standard consumer quality |

Ruggedized for industrial/commercial use |

|

Compliance |

HDMI standard |

HDMI standard + industry-specific standards |

By offering this flexibility, custom HDMI cables deliver reliable performance in demanding environments where standard products fall short. For industries like broadcasting, digital displays, or interactive kiosks, professionally manufactured and expertly managed solutions ensure high-quality transmission and seamless integration into specialized installations.

Is making your own cables worth it?

While it may seem cost-effective at first, making your own cables rarely delivers the performance, compliance, or durability required for professional applications. Rudimentary or improvised solutions are not only unreliable but also risky, as they can lead to signal loss, overheating, or premature wear.

In regulated industries such as healthcare, aerospace, or defense, non-compliant cables can even create liability issues. Reliable cable manufacturing demands specialized equipment, strict quality control, and adherence to safety regulations—all of which require significant expertise and investment. This is why it is always safer and more efficient to rely on experienced professionals. By partnering with Source Engineering & Manufacturing, you ensure that every step—design, material selection, assembly, and testing—is managed by experts following rigorous processes that guarantee safety, compliance, and long-term performance.

To better illustrate the trade-offs, here’s a quick comparison:

|

Factor |

DIY Cable Making |

Professional Manufacturing (Source Engineering) |

|

Upfront Cost |

Low materials, high tooling/time |

Streamlined, predictable investment |

|

Reliability |

Inconsistent, prone to failure |

High-quality, tested to meet industry standards |

|

Compliance |

Noncertified |

Fully compliant with safety and performance regulations |

|

Efficiency |

Time-consuming |

Scalable from prototyping to mass production |

|

Long-Term Value |

Higher maintenance/replacement |

Longevity, reduced downtime, cost savings |

Ultimately, professional manufacturing isn’t just a safer option—it’s the smarter investment. It guarantees that cables perform as intended, extend system lifespan, and protect businesses from costly failures.

Need precise, application-specific cabling solutions? Source Engineering & Manufacturing specializes in custom cable manufacturing for medical, defense, industrial, and commercial applications. Trying to manage cable assembly in-house exposes you to risks—missed compliance, failed quality checks, and costly delays that can impact your entire operation.

At Source Engineering & Manufacturing, UL certifications and ISO compliance, quality systems, and compliance processes are already built in, giving you reliability and efficiency from day one. From raw materials to the finished product, we deliver speed, quality, and peace of mind. Don’t take unnecessary risks—partner with the experts who do this every day. Connect with us at www.sourceeng.com to request a quote or schedule a consultation.

.png?width=1584&height=396&name=BANNER%20SOURCE%20(2).png)

.png?width=400&name=Source%20Engineering%20Blog%20(4).png)